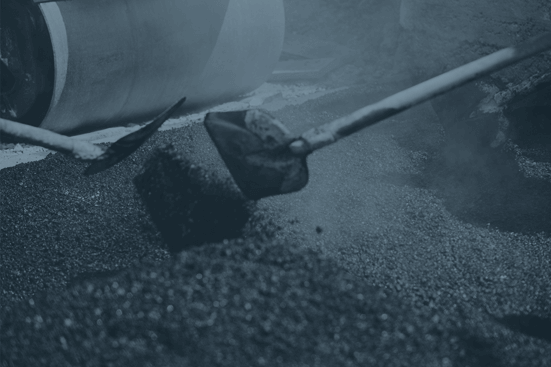

1. Increase useful life

Adding rubber powder to asphalt makes it more resistant to cracking, rotting and wear in asphalt. This increases the useful life of the asphalt and requires less maintenance over time.

2. Improved moisture resistance

Adding rubber powder to asphalt makes it not absorb moisture caused by rain and contact with water. This reduction in moisture absorption helps the asphalt to improve its resistance to water, cracking and rotting.

3. Optimizing properties

The addition of rubber powder to rubber formulations can bring significant improvements in properties such as wear resistance, heat resistance, oil resistance, chemical resistance, and impact resistance.

4. Improvement of mechanical properties

The use of rubber powder in asphalt improves its mechanical properties, including increased flexibility and resistance to cracking. This improvement in the mechanical properties of asphalt can lead to savings in maintenance and repair costs.